Intercooler pipe – how to troubleshoot?

An intercooler is found in every turbocharged engine. Most often found on diesel versions of engines, however, in modern cars, an intercooler is also found on gasoline engines. This part does not require serious operating costs, but at the same time it is an important part of the turbo engine.

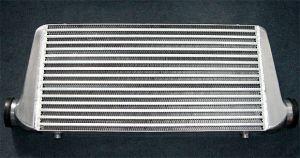

1 Intercooler is an important component of a turbocharged engine

The intercooler is a special heat exchanger that is located between the engine intake manifold and the turbine. The quality of an intercooler in a car is indicated by the amount of compressed air it can remove. They come in different sizes, and the main criterion for the effectiveness of this part is the area of u200bu200bthe heat exchanger, which also differs for different types of engines. It is worth remembering that an increase in the heat exchanger area is not directly proportional to an increase in efficiency, since even a 100% increase in area will give an increase of no more than 10%.

In addition, the quality of the connections depends on the efficiency of work, with which many owners of modern cars often have problems. In order to understand the main problems that can arise with the connection tube, it is necessary to understand what an intercooler tube is and to determine its role in the heat exchange system. It should also be remembered that the shorter the length of the connecting pipe, the more efficient the entire system will be.

2 Intercooler connections

Loss of one of the connecting tubes can lead to severe losses in engine power and efficiency due to loss of pressure in the turbine, which will "eat" the oil, causing the air mass meter and other sensors in the system to malfunction. The most common problem is a broken or damaged intercooler cooler hose, causing the engine to stop working properly and the sensors to not count the amount of air supplied.

Oil also appears on the articular surface. If a branch pipe (the connecting element from the turbine to the repaired intercooler) has failed on your car, then the car’s engine is under heavy load. Therefore, when replacing a combustion pipe, it is necessary to correctly calculate the load on this part, it is calculated based on the boost pressure indicator and the cross-sectional area.

3 Problems with the intercooler pipe and how to solve them

A malfunction of the intercooler and its individual systems leads to a noticeable loss of pressure and, as a result, to the gradual destruction of the entire engine system. That is why, in case of malfunctions, urgent repairs are required, which should be carried out in a technical center. Specialists will assess the degree of damage, after which it will be possible to conclude whether it is necessary to replace the plastic or aluminum pipe or whether it is enough to work with sealant or argon.

If you find oil on the surface of the connecting pipe from the intercooler to the turbine, this is not a reason to consider this connection to be leaky or faulty.

It all depends on the amount of oil at the junction, because even on a serviceable pipe you can find oil that is “pushed out" by the turbine, especially for cars with high mileage and diesel engines. However, if there is a lot of oil on the hose, this means a broken connection and requires an urgent replacement of the hose or a special o-ring from the turbine to the intercooler if there is oil on it. If your car’s system is leaking or there are cracks or holes in the hose, it is urgent to replace the connection and check the oil.

You can do the troubleshooting work yourself, but it is better to entrust the installation of a new pipe to experienced specialists, it will be safer and calmer. In the case of fastening with your own hands, you cannot be sure of the reliability of the connection to the branching. As for the specialists, they will select the most optimal option for a specific system and a specific car model, check the rest of the fasteners and the reliability of all connections, including the turbine itself, which is not recommended to be repaired on their own. Arms.

4 Conclusions and recommendations for the operation of intercooler pipes

Many experts recommend choosing a single connecting pipe as the pipe that bears the main pressure load, while the pipe itself must be made of a material that is durable and resistant to various temperatures, as well as deformation of the material if oil or fuel drops rise to the surface. At the moment, the most reliable connections are silicone tubing, which can withstand high temperatures, providing a reliable connection. However, different hoses may be suitable for different engine models, so it is worth consulting with specialists and, if possible, diagnosing the entire system.

And it is very important to remember that it is not worth postponing or postponing the repair of this simple, but very important connection in the design, as this can lead to serious consequences for the turbine, which can simply fail due to constant overpressure. The quality of the pipe connection is easy to monitor, they can be periodically inspected with your own hands, making sure that no oil appears on the surface of the pipe, with the exception of a few allowable drops. In addition, constantly check the health of all elements of the engine system, and your car will enjoy reliable and trouble-free operation.