Low idle on a warm engine: causes and methods for solving a malfunction

Many fuel injected car owners have observed the effects when idle (XX) drops suddenly. Especially often this phenomenon occurs when the engine warms up to operating temperatures. Sometimes the RPMs drop so low that the engine stalls. Let’s take a look at what can cause low idle on a hot engine, and also find out why it drops. This information will be useful to everyone.

The origins of unstable engine operation on the twentieth

How will the image develop if the control unit does not receive data on the amount and volume of air consumed? So, for example, the response of the throttle sensor will be as follows: at first, the speed will increase, but then the fuel mixture will begin to lean, as a result of which the engine will be warmed up to low speed. There is only one reason for this: the amount of air consumed by the engine has decreased.

However, the opposite happens: the fuel mixture is enriched and the engine starts to pick up speed again. Such cycles can alternate indefinitely, these are floating revolutions. Especially relevant is the problem of low idle on a warm engine in winter.

In some cars, events can develop in different ways: the speed increases, for example, to 2000 rpm, and remains there. The reason is that the injector injects large portions of fuel. The amount of air does not increase, otherwise the engine could increase the speed to 3 thousand, but it would still start to stall.

Fuel quality

If the idle speed drops on a hot engine, do not dump fuel. The problem may not be related to the electronics, sensors, or actuators. Perhaps the whole point is that the driver refuels with low-octane gasoline, and the ECU is designed for high-octane brands. Hence the lean mixture, so the control unit has no choice but to work like this.

Possible reasons

So what is causing this problem? One of the most vulnerable parts of injection engines are sensors. One of the elements that directly affect the operation of the engine and its quality is the idle speed sensor. It can often be found near the throttle body. This is a stepper motor with a conical closing needle. When the throttle valve is closed, air enters bypassing the valve through the idle channel, which is blocked by a needle.

Another culprit for very low idle is the MAF (Mass Air Flow Sensor). Air is the second important component for the preparation of the fuel mixture after gasoline. Therefore, if the mixture is very poor, then there is nowhere to twist.

If the system malfunctions, the ECU cannot correctly select and calculate the ratio of the fuel mixture in XX mode. As a result, the motor will work unstably, the speed will begin to decrease and increase.

A less common cold idle problem with a warm engine can be a malfunction of the EGR system, or rather its valve. The element is installed in the intake manifold and its function is to remove exhaust gases. It is nothing more than a crankcase valve. The sensor needs to be cleaned periodically.

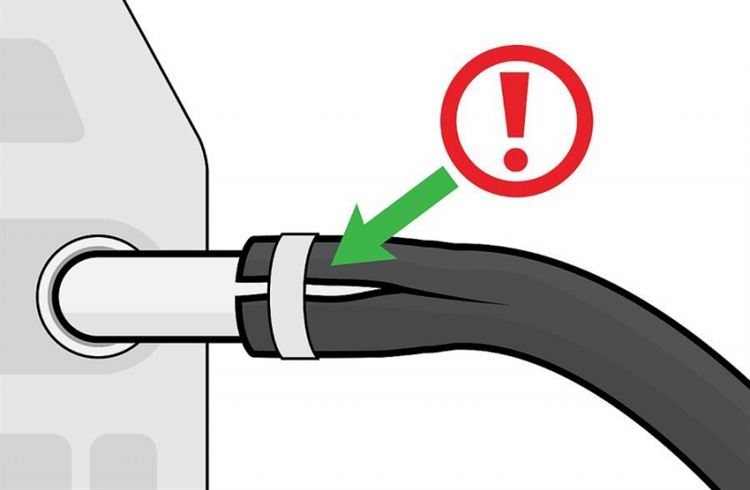

It also does not hurt to make sure that there is no air leakage in the system and check the condition of the throttle. Often the problem of low speed can be associated with a dirty shock absorber or its mechanical damage, deformation. It often happens that for one reason or another the shock absorber sticks, hence another reason for low revs.

Why do sensors die?

Experts identify two reasons for low idle speed. One of them is related to the poor quality of fuel. Often a low octane number not only heavily pollutes the working surface of the sensor, but can also cause various malfunctions of electronic components.

Also, often the sensors fail due to a banal marriage or exceeding the service life. Inexpensive sensors may be of poor quality or defective. That is why the car appears low idle.

How to eliminate air leakage?

To exclude or confirm the leakage of unaccounted for excess air into the system, check the tightness of the air supply system.

To do this, you can remove the air pipe and blow from the compressor or pump. The hose can be placed in water. This will reveal cracks and other defects.

How to check the idle speed sensor?

It is recommended to use a multimeter to check if the sensor is working. The verification procedure is very simple. Replace the resistor between the contacts on the sensor block. It is important that the ignition is on. The resistance between different pairs of contacts should be between 39.5 and 81 ohms. If during measurements the multimeter gives other readings, then the sensor must be replaced.

Checking the DMRV

So, first, to check the DMRV, turn on the ignition. You need to check the voltage with a multimeter. Measure it between the green and yellow wires. In different cars, the voltage can vary from 0.9 to 1.2 V. You can determine the output of the mass air flow sensor by the appearance of the candles – black soot indicates that it is better to replace it.

How to clean the idle speed controller (IAC)?

When a low idle problem occurs with a warm engine, a DXC flush can solve the problem in some cases. To do this, turn off the power to the car. The regulator is located on the throttle valve, below the TPS (throttle position sensor). It is necessary to prepare a clean rag, a screwdriver, liquid in a can; It can be any carburetor or injector cleaner.

Cleaning begins with disassembly: to remove, just unscrew the fixing screws. Sometimes there are bolts. By removing the sensor from its seat, you can begin the cleaning process. The work is carried out with the help of a liquid-treated rag from a can.

It is also necessary to spray from a can onto a needle. The latter in various car models can be made of metal or plastic. The cleaner will not damage the plastic. But the liquid must not get under the spring. In this case, it is recommended to blow out the sensor with compressed air as soon as possible. If this is not done, the fluid will wash out the internal lubrication, resulting in complete failure of the IAC.

Conclusion

As you can see, just a few sensors can lead to low engine idling. But even a small element can significantly ruin the life of a car owner, especially if the speed does not always decrease. But this is not a problem, because this problem can be solved easily, without large investments.